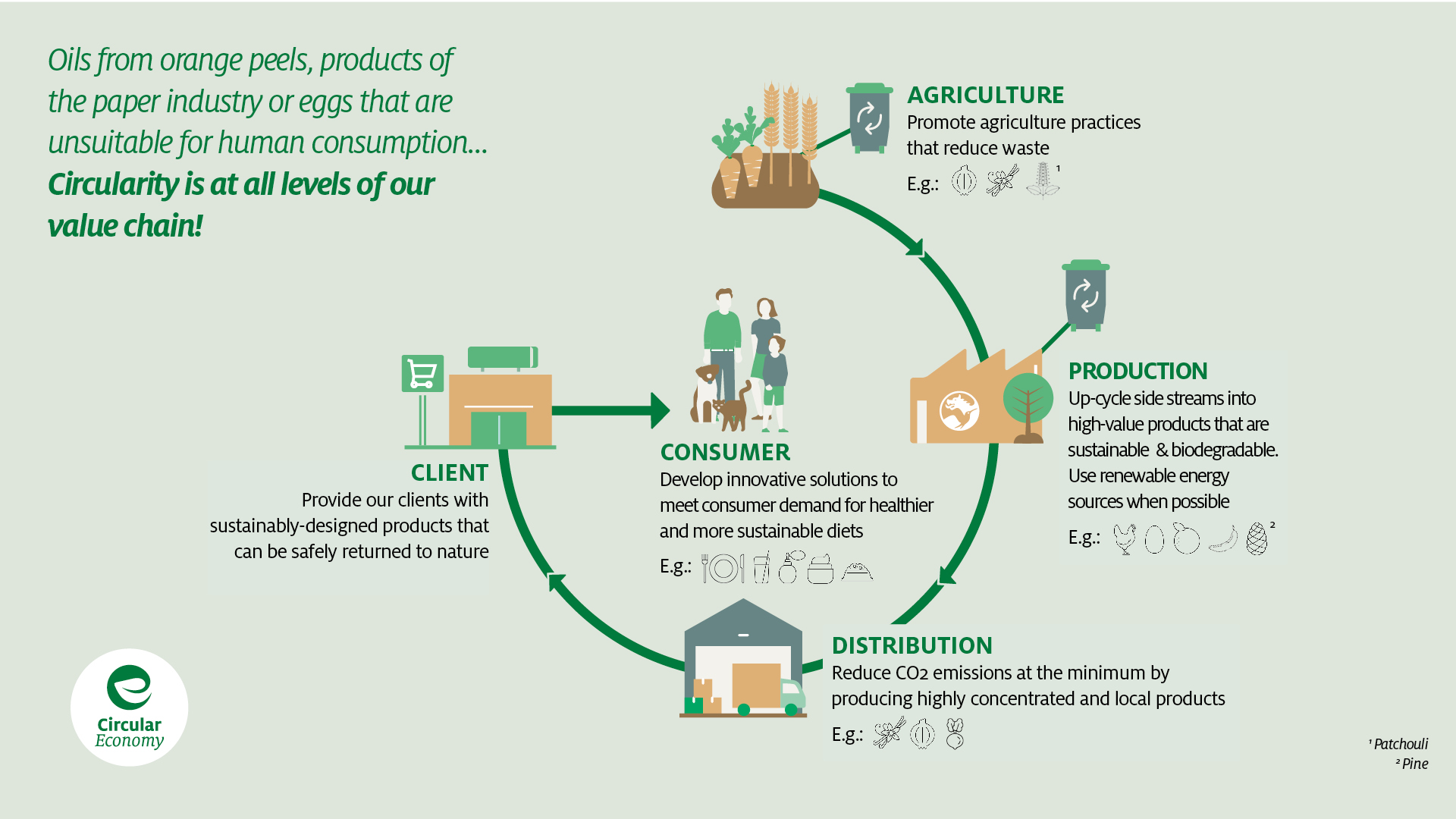

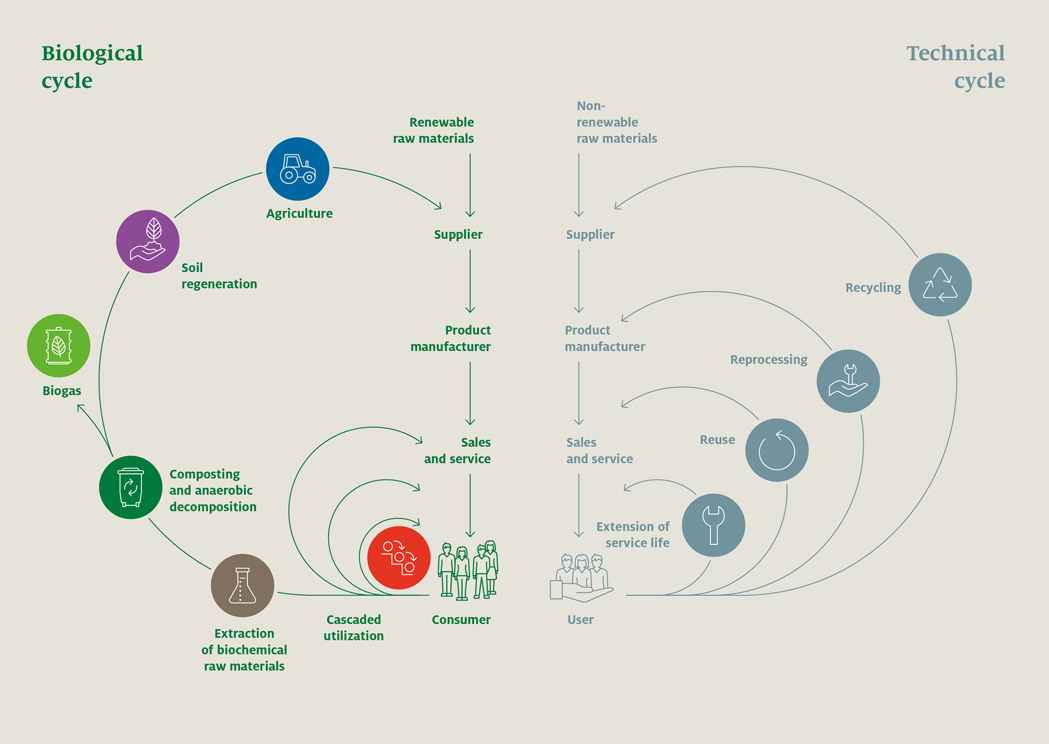

Symrise applies the principles of the circular economy across all levels of the value chain. The circular economy is based on principles that we implement in various projects, products and processes at Symrise.

We want to focus on cycles as much as we can – by using 100 % of raw materials when possible, avoiding waste, and returning side-streams to processes. This allows us to meet production demands and continue to grow while decoupling resource consumption from growth, thus going far beyond traditional recycling.