How Haarmann & Reimer chemists transformed the future of menthol

The origins of Symrise’s predecessor, Haarmann & Reimer (H&R), date back to 1874 when the synthesis of vanillin was developed. This breakthrough was followed by numerous other significant inventions and practices that shaped the industry. Fifty years ago, another important milestone was achieved with the first commercial total synthesis of l-Menthol on an industrial scale.

On September 3, 1974, Haarmann & Reimer filed a groundbreaking patent for the “separation of optically pure d- and l-isomers of Menthol, Neomenthol, and Isomenthol”. Based in Holzminden, the company became the first in the world to successfully operate a large-scale plant for the production of synthetic l-Menthol. This industry-changing innovation was developed by Jürgen Fleischer, Kurt Bauer, and Rudolf Hopp after nearly a decade of intensive research and development. But what made Menthol such an appealing target for synthetic production?

The origins of Menthol cultivation

Menthol is pale white, crystalline, solid at room temperature and is classified as a monocyclic monoterpene alcohol. L-Menthol, known for its characteristic fresh, minty, and cooling sensation, is the dominant component in mint oils. These oils are typically extracted from Mentha Arvensis through steam distillation. In addition to l-Menthol, other key components of these oils include Menthone, Isomenthone, and Menthyl acetate.

Japan was the traditional menthol supplier before 1939. It covered around 70 to 85 percent of the world demand, which amounted to several hundred tons, with small quantities of Menthol coming from China. Due to the events of the war and the partial interruption of trade routes, they were no longer able to meet the demand.

The cultivation of Mentha Arvensis in Brazil, introduced by Japanese migrants in the 1920s, saw significant growth during 1942 and 1943. This surge resulted in the extraction of around 1,200 tons of crude mint oil, establishing Brazil as the world’s largest producer and supplier of Menthol at that time. However, over the decades, China eventually replaced Brazil as the primary supplier. Today, India has emerged as the largest producer of natural menthol, driven by extensive cultivation of Mentha Arvensis and advancements in extraction techniques.

Menthol’s rise to fame

Menthol only gained importance during the Second World War and especially in the 1950s. While in the Western World it was previously used almost exclusively in the pharmaceutical industry because its pharmacological value had been recognized, the real upswing came as a result of industrial restructuring and the creation of the consumer market by the USA. Freshness and the cooling effect became increasingly important as characteristic properties, especially in products for the dental care and confectionery industries. Progressive general prosperity further boosted mass consumption, particularly in these product groups, awakening new needs and opening up previously unnoticed markets. Menthol consumption increased accordingly.

The Breakthrough in Synthetic l-Menthol

To address the ever-growing global demand for Menthol, synthetization emerged as a highly promising and economically viable solution. The cultivation of Mentha Arvensis, especially in Brazil, had natural limitations. The specific young soil of the tropical-subtropical jungle, essential for Mentha arvensis cultivation, was available only in restricted quantities. Furthermore, modern agricultural techniques —requiring mechanical cultivation, irrigation, and meticulous soil care— made Mentha Arvensis cultivation costly, even with improved oil yields.

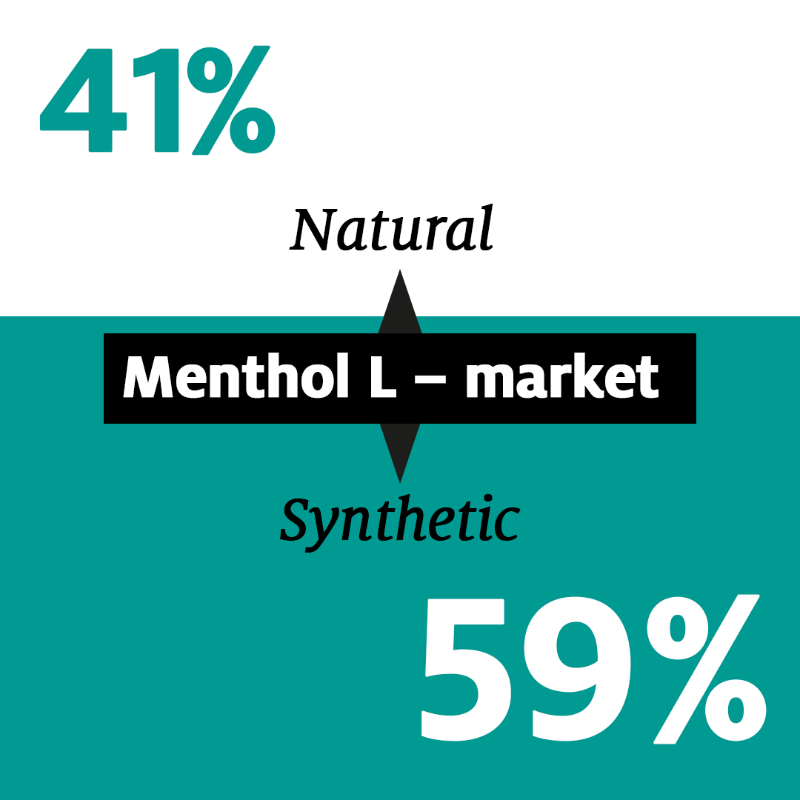

The groundbreaking success of Jürgen Fleischer, Kurt Bauer, and Rudolf Hopp revolutionized the menthol industry. Their innovation led to the development of synthetic menthol, branded as "Menthol H&R," which quickly gained global recognition. This marked a pivotal shift in the industry, as synthetization offered a reliable and scalable alternative to natural sources.

The heart of the innovation is still the separation of the two enantiomers d- and l-Menthol to obtain high-quality l-Menthol. This process, perfected by Haarmann & Reimer, ensured that synthetically produced menthol was chemically identical to its natural counterpart. As the company’s 1974 employee magazine Contact proudly stated: "Once the teething troubles have been overcome, a very considerable proportion of the world's menthol requirements will soon be produced synthetically."

One of the key benefits of this innovation was the purity of the final product. Pure l-Menthol, regardless of whether it is natural or synthesized, delivers the same quality in terms of flavor, scent and functionality. Haarmann & Reimer’s process offered a stable, high-quality supply, free from the uncertainties of harvest fluctuations, supply shortages, and price volatility. By economically splitting d/l-Menthol into pure l-Menthol using inexpensive raw materials from organic chemistry, the company was able to offer a product indistinguishable from the natural version.

Symrise's commitment to innovation extends beyond producing pure l-Menthol, they integrated circular economy practices for optimal resource utilization. For nearly 50 years, Symrise has perfected a state-of-the-art process to produce l-Menthol, the process separates l-Menthol from d-Menthol in the final stage of refinement. Ultimately, d-Menthol is recycled back into the process, resulting in nearly zero waste and minimizing environmental impact.