New approach: Green chemistry

Turning the dial back to natural materials isn’t quite so easy, however. “For some ingredients, we’re looking for alternatives to synthetic products in raw materials from nature,” explains Panten. For years, Symrise has also used the residual materials from production processes involving natural raw materials. “We apply the principles of green chemistry by avoiding waste and adding value to byproducts.”

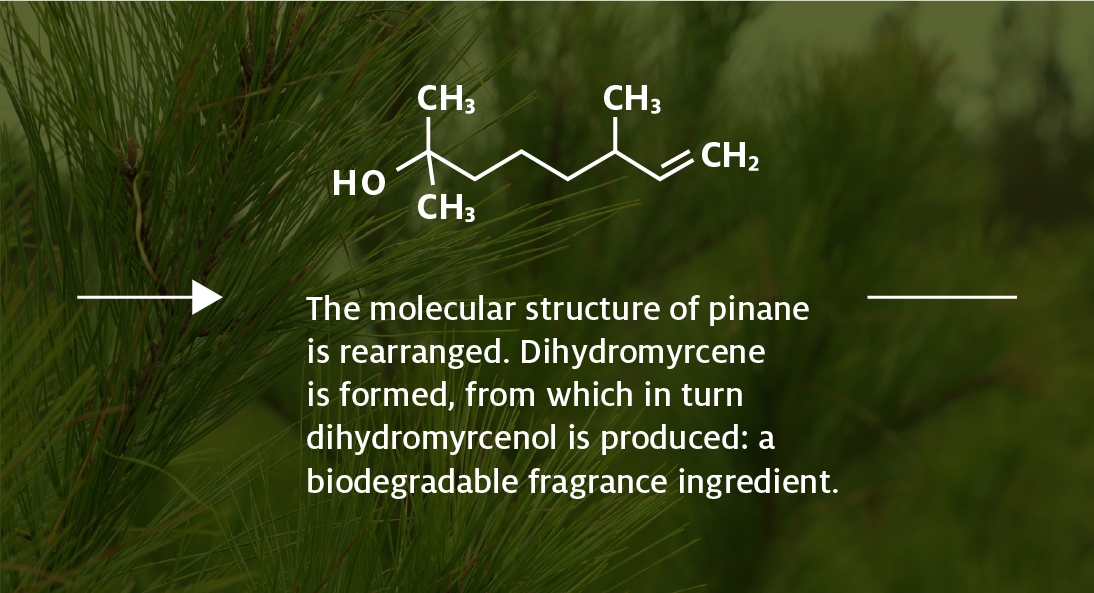

One example of this is dihydromyrcenol. Thousands of tons of it are needed on the global market, making it one of the most important fragrance ingredients. With its citrusy and herbal scent, it is used in perfumes, shampoos and cleaning products. The material comes from a byproduct of paper production. Johannes Panten grabs a marker and sketches out the process on a flip chart. A highly simplified process, of course, because the chemical reality is naturally a lot more complex. “It all begins in the pine forests of North America, where the wood is grown sustainably. It is then processed into pulp for paper production using the Kraft process. This process creates the byproduct raw sulfate turpentine oil,” explains Panten. The Symrise plant in Jacksonville, Florida, uses this byproduct and removes the sulfur, which has been added earlier in the process in the form of a solvent. Finally, the company breaks the material down into alpha- and beta-pinene – volatile liquids with a turpentine scent –and uses hydrogenation or pyrolysis to transform them into biodegradable fragrance and flavor ingredients: linalool, citronellol, geraniol and, of course, dihydromyrcenol.