We already do many things to ensure this:

we utilize our unique and patented processes to transform byproducts

we design chemical processes that reduce waste and reduce demand on diminishing resources

we create renewable alternatives to fossil crude oil based feedstocks

we develop earth-friendly ingredients that touch our lives every day

All of these successes are made possible by our commitment to continuous innovation and adherence to the tenets of ‘Green Chemistry’.

A responsible celebration of nature’s bounty

Whether due to natural shifts or man-made interventions, there’s little doubt that the planet around us is changing and evolving in ways that we all must adapt to.

At Symrise, we’re aware of how precious our resources are, and we’re proud to have been a responsible company for over a century. We make every effort to conserve resources and transform those we use in the most efficient manner to minimize our impact on the planet. Every Symrise ingredient and solution is in some way a celebration of nature’s bounty, and the people who work with it so skillfully. This includes everybody from the tireless farmers who harvest the land to the trailblazing scientists who draw out nature’s finest qualities.

Accelerating Green Chemistry practices and solutions

Green chemistry uses a clear set of principles. It applies to the design, development and implementation of chemical products and processes. They shall reduce or finally eliminate the use or generation of sensitive materials. This refers to the full life cycle of a chemical product.

As a leader in renewable materials, we are accelerating this approach. We are using by-products from our partners in the pulp & paper industry, orange juice and sugar cane industry. We maximize their use through innovative and patented processes. They enable us to create sustainable & renewable fragrance ingredients from excess material. With this approach, we are targeting a Zero Waste future.

Almost all of our large-scale FISC achievements wouldn’t be possible without our underlying commitment to the principles of Green Chemistry, from sourcing natural and renewable feedstock wherever possible to drastically reducing the amount of wastewater.

FISC stands for the four core pillars at the heart of our Sustainability strategy: Footprint, Innovation, Sourcing and Care.

FOOTPRINT

Minimizing our environmental footprint across the value chain

INNOVATION

Maximize the positive social & environmental impacts of our products

SOURCING

Maximize the sustainability of our supply chain and raw materials

CARE

Improve the well-being of our stakeholder communities

Green Chemistry in action

A Green Chemistry approach is built on a commitment to the innovations and continual improvements that lead to safe, eco-friendly processes and products.

Crude Sulfate Turpentine (CST) Transformation:

a remarkable process

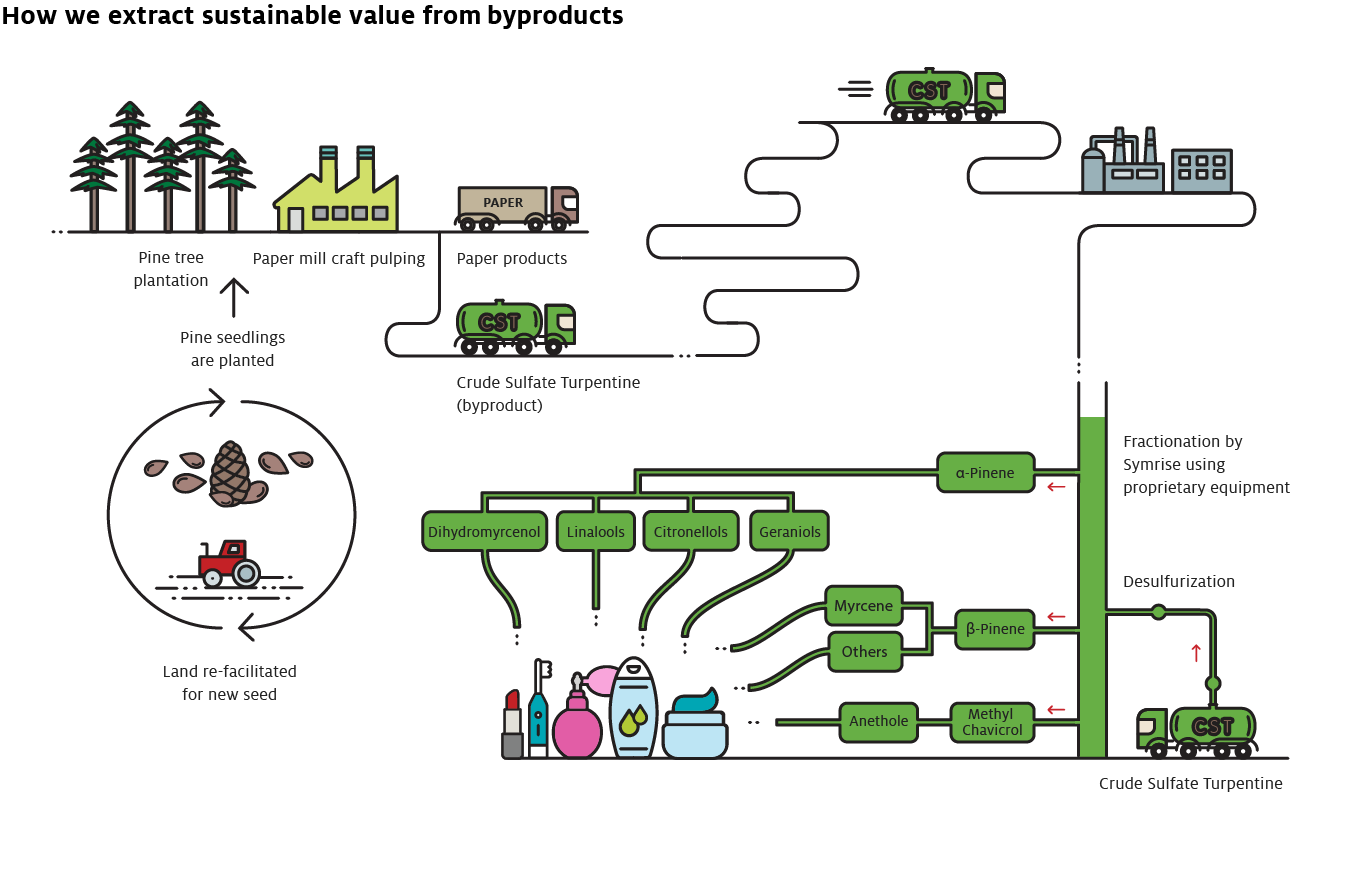

Much of our local, natural forest resources are located in the heart of the south-eastern United States. Here, our partners in the pulp & paper industry plant and harvest pine trees sustainably to produce paper products. When they pulp the pine trees in their facility, a by-product called Crude Sulfate Turpentine, or CST, is produced.

Traditionally this would have gone to waste, but we recognize the value of this by-product and source it directly from our paper mill partners for use in our aroma molecules facility in Jacksonville, Florida. Our innovative team of scientists and engineers developed processes that transform the natural and renewable by-product into a range of high quality ingredients used in personal care, beauty care and everyday household products available all over the world.

It is truly remarkable to see the processes that have developed here over the years.Dr. Peter Esser, Vice President of Global Chemical Production at Symrise

A closer look at a process spanning generations

Realizing the inherent value of these terpenes was just the beginning of a decades-long attempt to find ways of successfully extracting the different terpene building blocks. The pulping process results in a mixture of different terpenes being isolated as a by-product called crude sulfate turpentine (CST), a flammable liquid released from the pine wood chips during the kraft pulping process. Our chemists and engineers were tasked with finding a way of safely and sustainably obtaining the valuable terpenes from CST.

The result is a finely-crafted process that separates CST into a number of valuable and renewable materials which can be transformed into various fragrance and flavor molecules.

CST

We transform this natural and renewable by-product into a range of high quality ingredients

One of the key figures in this remarkable achievement is the Jacksonville plant’s Head of Research and Development, Gene Kolomeyer, who has spent more than 20 years working on how to efficiently convert the terpenes from CST into value-added products.

The processing starts with separating the CST into its main components: alpha-pinene and beta-pinene. Once this has been achieved, further chemical transformations allow us to create valuable fragrance molecules that replicate those that naturally occur in plants such as rose, geranium and lavender. While generating floral scents from paper byproducts may sound like a minor miracle, the reality boils down to a tireless scientific approach. “The basic material remains the same, with its ten carbon atoms. We just modify it and recompose it,” explains Gene. “That isn’t magic – it simply takes expertise and hard work to define the right chemistry. We then optimize the various reaction variables, such as temperatures, pressures and durations to produce the best results.”

20 years

The time we spent perfecting the process that makes this possible

From orange peel to oral care

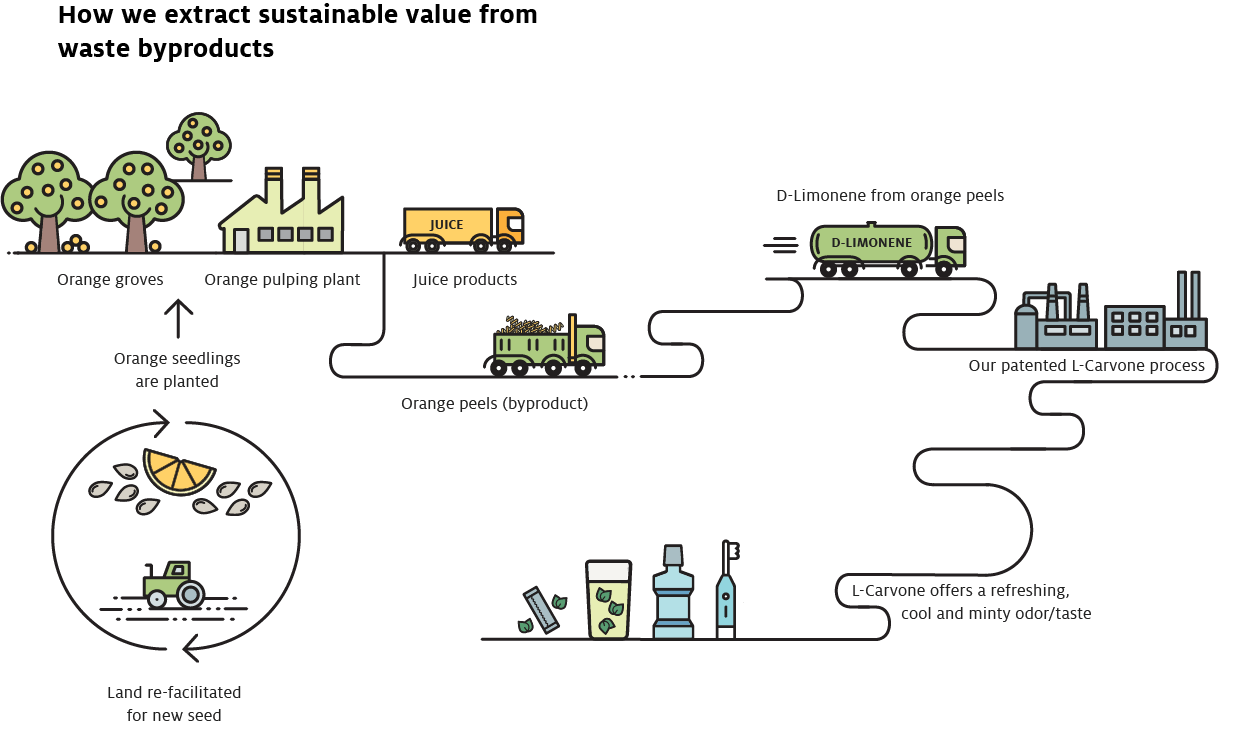

It’s not only CST from pine trees from which we’re able to innovatively source useful ingredients. Our Jacksonville team has also designed and patented a truly green proprietary process for delivering l-Carvone from d-Limonene, a by-product isolated from the orange peels of the orange juice industry.

Our unique process produces ultra-pure l-Carvone, free from chlorides, nitrogen compounds, solvents and toxic reagents. We achieve this using the most environmentally-friendly production methods possible, having developed a process that eliminates millions of liters of wastewater annually, in comparison to more traditional methods.

The end result is an ingredient that provides a refreshing, cool and minty taste to a range of everyday oral care and confectionery products, while also embodying our commitments to sustainability and innovation.

Finding the fruitiest flavors

Back in Germany, scientists at our Holzminden headquarters are also working on green methods for harnessing aromas and tastes from natural plant materials. In the early 2000s, we began working on a process that optimizes the recovery of natural flavor molecules from fruits like apple, strawberry and raspberry. After eight years of meticulous research and development, we finally patented the resulting technology: the award-winning SymTrap® Technology.

SymTrap® works by capturing side streams produced in fruit processing. It concentrates the natural aromatic fruit ingredients present in the water phase, which can then be infused into the end product. Based on ingenious adsorption and desorption processes, the technology provides an intelligent, highly-effective application of physical principles. SymTrap® also requires minimal processing, giving the end products a more natural and authentic taste. This contributes further to the process’ ‘green’ credentials, as no heating means it only requires low amounts of energy.

More recently, we ushered in the ‘next generation’ of SymTrap® products. The SymTrap® technology not only extracts and concentrates flavoring substances from side stream – it also allows for gentle methods that concentrate secondary plant metabolites with bio-functional properties. These properties are increasingly sought-after by consumers around the world.

As we continue to refine and evolve our SymTrap® processes, one thing remains at the core of our ambitions: we want to extract these substances from their natural sources as gently as possible, so that consumers and our clients get exactly what they’re looking for: great tasting solutions that are also compatible with a healthy lifestyle.

A greener future

Despite all of our achievements to date we recognize that, for a business like ours, sustainability is a constantly evolving and ongoing journey – one that we continue to tackle with energy and urgency.

While we’ve shared just some examples of Green Chemistry in action here, we’re applying the principles in many different parts of the business – it’s at the heart of our responsible and pioneering approach.

Prevention

Atom Economy

Less Hazardous Chemical Syntheses

Designing Safer Chemicals

Safer Solvents and Auxiliaries

Design for Energy Efficiency

Use of Renewable Feedstocks

Reduce Derivatives

Catalysis

Design for Degradation

Real-time analysis for Pollution Prevention

Inherently Safer Chemistry for Accident Prevention